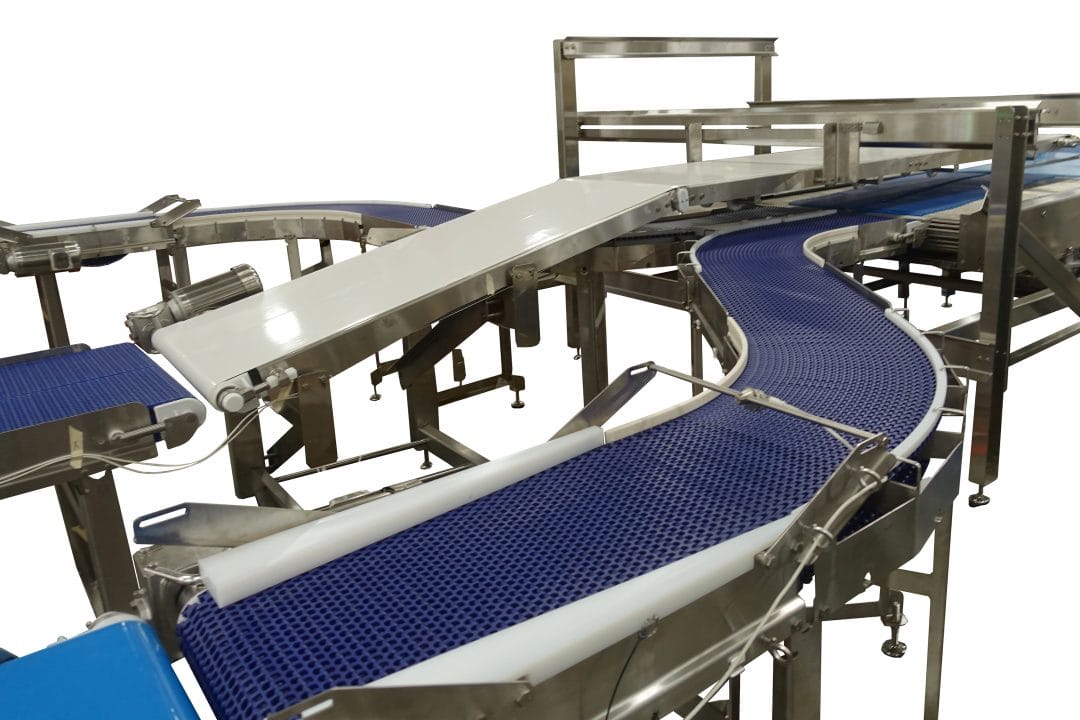

Conveyor belts play an essential role in just about every industrial process. They transport materials, parts, or products from one area of the facility to another quickly and effectively. However, not all conveyor belts are created equal. Some create problems with rollbacks, spillages, and blockages, especially in the presence of grade changes and turns. Custom belt cleats provide a perfect solution.

What Are Belt Cleats?

Belt cleats, also referred to as lugs, flights, or profiles, and are integral parts of many conveyor systems. They create a widely serrated surface that provides consistent product spacing and helps to avoid rollbacks and spillage on steep inclines and declines.

Types of Belt Cleats

Belt cleats can be made from a variety of materials and can be custom-fabricated to suit unique applications. Common materials for belt cleats include:

-

Polyvinyl Chloride (PVC)

-

Polypropylene (PP)

-

Polyethylenes such as HDPE, MDPE, LDPE, or PET

-

Thermoplastic elastomers (TPE)

-

Custom compounds

Deciding on the right material isn’t the only choice customers have when it comes to choosing the right system. Cleats can also be fixed or removable, and they can be custom-manufactured to have specific characteristics. Some belt cleats have flat profiles, while others are rounded. Some profiles even have sidewalls for maximum reduction of spillage and rollbacks.

Benefits of Custom Belt Cleats

High-quality belt cleats can optimize the functionality of any conveyor system. They make it easier to convey materials at fast speeds or on extreme grades while simultaneously making it possible to separate them easily. Belt cleats can:

-

Increase the handling capacity of conveyor belts by reducing material rollback

-

Reduce spillage by keeping the products on the belts as they move around turns

-

Create opportunities for reducing capital costs by allowing for steeper conveyor system designs

-

Speed up the manufacturing or packaging process by allowing for faster speeds

Almost every industry relies on conveyor belts for manufacturing, processing, or packaging. Many of these companies could benefit from installing high-quality custom belt cleats on their conveyor systems. See https://www.cir.net/ for more.

Common Applications for Belt Cleats

Just about every industrial facility features some kind of conveyor system. Belt cleats can improve efficiency, speed, and system design in the vast majority of these applications. They’re particularly useful for:

-

Recycling and waste management

-

Mining

-

Food processing

-

Chemical and pharmaceutical manufacturing

-

Packaging, shipping, warehousing, and sorting

-

Bottling and canning

-

Agricultural operations

-

Original equipment manufacturer (OEM) fabrication

-

Automotive and aerospace industry applications

If the facility has limited floor space, belt cleats may enable steeper grade changes and the use of shorter belts to free up more room. Depending on the materials being processed or transported, they may be a necessity rather than a luxury.

Choose a Reliable Belt Cleat Manufacturer

Choosing the right custom belt cleat fabricator is very important since it affects the quality of the final product. California Industrial Rubber Co. has the ability to manufacture cleats for a variety of unique applications. Customers can choose from a variety of configurations and materials, and they can work directly with the company to make sure their custom products will be perfectly suited to meet the company’s needs. Visit https://www.cir.net/contact-us/ to learn more.

Media Contact

Company Name: California Industrial Rubber Co.

Contact Person: Media Relations

Email: Send Email

Phone: 559-268-7321

Country: United States

Website: https://www.californiaindustrialrubber.net/