With the promotion of new energy policies and the increasing awareness of environmental protection and low carbon, the global automotive market is changing from fuel vehicles to hybrid vehicles and pure electric vehicles.

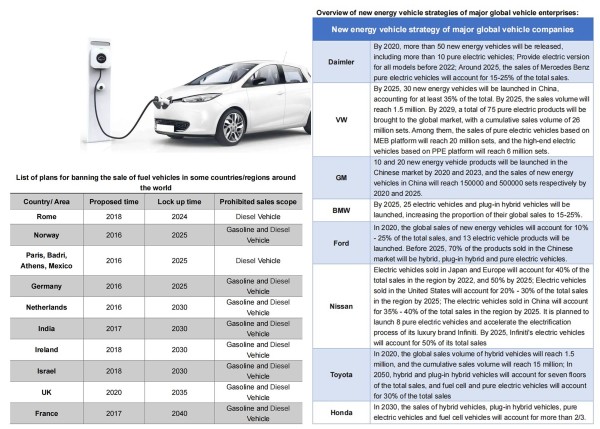

EU carbon emission assessment requirements: average carbon emissions of 95% of vehicle models will be reduced by 95g/km in 2020, and all vehicle models will meet this carbon emission requirement in 2021. According to this requirement, it is estimated that the electrification rate in Europe in 2021 will be about 10%, and the sales volume of electric vehicles will be about 1.6 million. At present, several countries/regions have clearly proposed the time for banning the sale of fuel vehicles.

In addition to countries and regions actively promoting new energy vehicles, major global automobile enterprises have also successively released new energy vehicle strategies, especially traditional fuel vehicle giants.

l Requirements of leakage current detection on new energy charging Equipments

With the continuous growth of new energy vehicles, electrical safety accidents of electric vehicles occur frequently, and electrical safety issues are put on the agenda. According to incomplete statistics, in the past, electrical fire accidents caused by excessive residual current in electric vehicle charging accidents accounted for a large proportion. At the same time, electric vehicle charging, especially the charging pile, may be in an extreme climate environment (urban rainstorm, waterlogging, etc.) in various cities. In order to ensure safety, the charging party and the operator urgently need the real-time residual current information of the charging pile.

The AC/DC link is used in the new energy vehicles as the conversion and transmission of electric power. In the AC/DC conversion link, transmission and use process, there will inevitably be DC residual current. In addition to the traditional power frequency residual current, it may also be AC, smooth DC, pulsating DC and composite AC/DC residual current of various frequencies, that is, the scope covered by type B residual current.

At present, the internal functions of on-board charger (OBC) are increasing, the circuit topology is also growing, and the circuits such as EMI filtering, rectification and PFC power factor correction are becoming more and more complex. The traditional AC/A residual current protector cannot fully respond to the complex current generated by it. Even when there is high-frequency leakage current or DC leakage current component, it will lose the basic AC leakage protection function. When smooth DC leakage occurs, Only Type B RCDs can be protected.

At present, the new energy charging pile is in the early stage of industrial development, and all aspects of the charging equipment industry are not perfect, subject to technology and cost. At present, almost all residual current protectors in the pile in China are Type A, and some compromises have been made in many aspects, resulting in the uneven quality of charging equipment, which will bring certain potential safety hazards. The safety of charging equipment is directly related to the subsequent development of the electric vehicle industry, With the rapid development of new infrastructure, the proportion of charging piles to new energy vehicles will be closer to 1:1. As a charging pile supporting new energy vehicles, the safety and reliability of use have become the biggest challenge in the charging pile infrastructure industry. As an important responsible party, charging operators must ensure the safety of charging equipment, Residual current monitoring will also be developed from TypeA to TypeB, which is more safe and reliable.

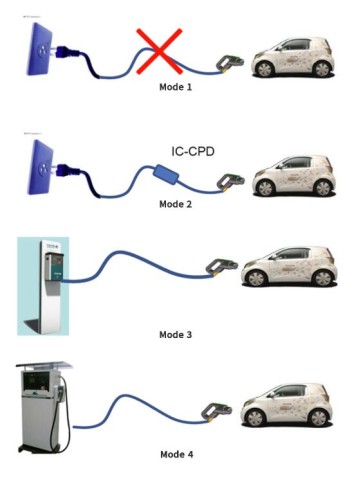

l There are four charging modes are defined in IEC61851-1 Electric vehicle conductive charging system – Part 1: General requirements:

- Mode 1 is a method for the connection of an EV to a standard socket-outlet of an AC supply network, utilizing a cable and plug, both of which are not fitted with any supplementary pilot or auxiliary contacts.

NOTE 1 In the following countries, Mode 1 charging is prohibited by national codes: US, IL, UK

- Mode 2 is a method for the connection of an EV to a standard socket-outlet of an AC supply network utilizing an AC EV supply equipment with a cable and plug, with a control pilot function and system for personal protection against electric shock placed between the standard plug and the EV.

- Mode 3 is a method for the connection of an EV to an AC EV supply equipment permanently connected to an AC supply network, with a control pilot function that extends from the AC EV supply equipment to the EV.

- Mode 4 is a method for the connection of an EV to an AC or DC supply network utilizing a DC EV supply equipment, with a control pilot function that extends from the DC EV supply equipment to the EV.

l Harmfulness of leakage current

- Harm to human body

The harm of electric leakage is closely related to time. If there is an electric shock protection device, the current allowed to pass through the human body can generally be considered as 30mA, and 10mA is the safe current for the human body. DC electric leakage will also cause damage to the human body.

- Why a DC 6mA or a Type been required in IC-CPD and AC Charger/Wall-Box application?

Existing type A RCD can only in the detection of pulsating dc leakage from 6 mA dc current interference, and can’t detect dc leakage and disconnect protection, when dc leakage is more than 6 mA, due to the DC residual current will cause core magnetization in advance, make tripping value deviation, lead to type A RCD can’t normal movement, and therefore must use type B RCD or A+6 protection!

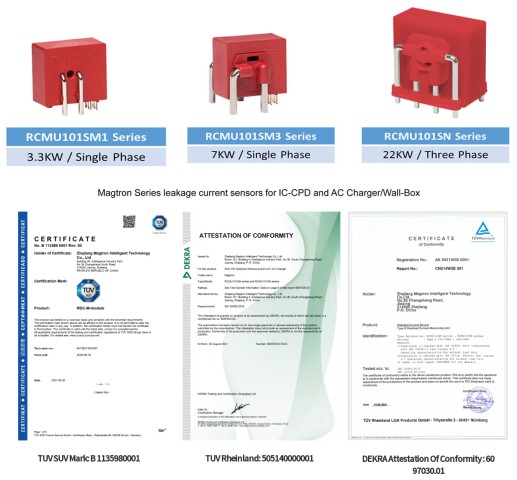

Magtron – All type Current Sensitive Residual Current monitoring Unit (RCMU Series Sensor) developed for EV-Charging Providing all-current sensitivity. The sensor can trigger an automatic shut-off (Trip) signal in case of hazardous electrical faults ( DC and AC ) according to IEC 62752 or IEC 62955. are widely used in electric vehicles charging systems — IC-CPD and AC Charger/Wall-Box application.

l Benefits:

- Protects against hazardous situations with fault currents, Preserving RCCB type A from saturation in case a smooth DC component in the circuit.

- Small volume and footprint for integration into compact IC-CPD and AC Charging Wall-box and Charging Piles.

- Robust mechanical and electrical design suitable for harsh environmental conditions.

- Electrical safety at low cost (compared to TYPE B RCCB).

- Integrated self-check functions.

l Applications (EV Charging Mode 2 and Mode 3)

- IC-CPD in charging Cables for electric vehicles (EV) and plug-in hybrid electric vehicles (PHEV).

- AC Charging Wall-box for EV and PHEV.

- AC Charging piles for EV and PHEV.

Media Contact

Company Name: Magtron Intelligent Technology Co.,Ltd

Contact Person: Morgan

Email: Send Email

Phone: +86-573-82660100

Country: China

Website: www.magtronworld.com