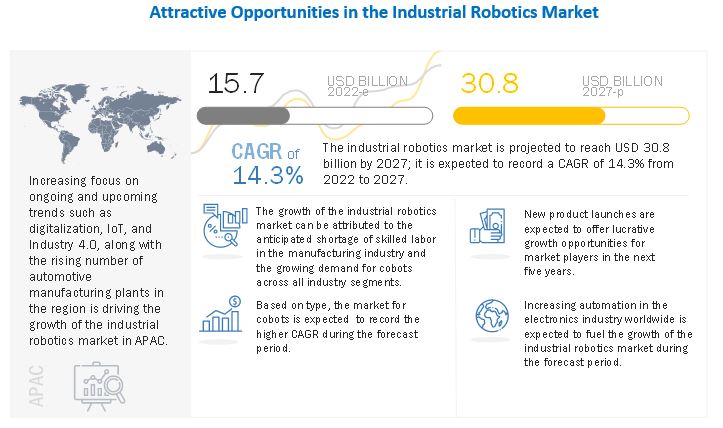

The Industrial Robotics Market is projected to grow from USD 15.7 billion in 2022 to USD 30.8 billion by 2027; it is expected to grow at a CAGR of 14.3% during the forecast period. Anticipated shortage of skilled labor in manufacturing industries and growing adoption of Industry 4.0 is one of the primary factors for the deployment of industrial robotics are factors driving demand of industrial robotics. Emergence of Industry 5.0 will boost the growth potential for industrial robotics in the coming years.

The growing demand for cobots across various industries and the increasing automation in the electronics industry are the key factors driving the industrial robotics industry.

• Informational PDF Brochure :-

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=643

Industry 4.0 refers to the current industrial revolution that is led by the evolution of robotics, automation, and the Internet of Things (IoT). Industry 4.0 and the Internet of Things are increasing the automation of previously manual tasks with a collection of real-time data, AI and device interconnectivity. Industrial robots are a special class of industrial equipment that perform such manual tasks efficiently, accurately, and with repeatability. For instance, the state of Michigan in the US launched the industry 4.0 initiative to equip small manufacturers with knowledge and resources to adopt Industry 4.0 technologies. The Chinese government has launched Made in China 2025, a state-led industrial policy that seeks to make China dominant in global high-tech manufacturing. According to China’s Ministry of Industry and Information Technology, Made in China 2025 is part of a three-step strategy for China to become a world leader in advanced manufacturing:

- China should equal the manufacturing power of Germany and Japan by 2025.

- China should be among the world’s top manufacturing powers by 2035.

- China should be the world’s top manufacturing power by 2045, having achieved innovation-driving capabilities, clear competitive advantages, and world-leading technology and industrial systems.

Browse 351 market data Tables and 86 Figures spread through 383 Pages and in-depth TOC on “Industrial Robotics Market by Type, Component, Payload, Application, Industry and Region – Global Forecast to 2027”

View detailed Table of Content here –

https://www.marketsandmarkets.com/Market-Reports/Industrial-Robotics-Market-643.html

The increase in automation is expected to enable electronics companies to innovate further, as they would be able to build prototypes in less time and with limited capital. Robots can be used across the entire production cycle in processes such as assembly, dispensing, milling, inspection, packaging, and palletizing. Advancements in end effectors and vision systems are also contributing to the push for robots. For instance, random bin picking enables robots to pick unsorted components from bins and mount them as per the required orientation. The demand for robot end effectors for electrical and electronic applications is also growing alongside the demand for industrial robots.

The degree of industrial automation has increased immensely in recent years due to increased productivity, reduction in labor costs, increased efficiency in production processes, and improvement in the quality of products. In the future as well, industries such as food & beverages, automobiles, and oil & gas will be more inclined towards automation due to the intense competition in the market and the need to stay ahead of competitors by improving the product quality and the speed of production. Robotics has transformed automation processes to a great extent. In recent years there has been a surge in the market for robot accessories such as end effectors and controllers. This demand is expected to escalate even further during the forecast period from 2022 to 2027.

Market in Asia Pacific to hold significant opportunities for the market during the forecast period

Asia Pacific is the leading market for industrial robotics in the automotive, electrical & electronics, and others with the major demand from China, India, and Japan. The countries of Asia Pacific are witnessing increased demand for industrial robotics, and this demand is expected to grow at a significant rate during the forecast period as well. The rising costs of labor in the APAC region caused SME industries to start integrating collaborative robots in their manufacturing processes to make operations more efficient and cost-effective. APAC is considered one of the world’s major manufacturing hubs and is expected to provide ample growth opportunities to the industrial robotics market. Low production costs, easy availability of labor, lenient emission and safety norms, and government initiatives for foreign direct investments (FDIs) are some of the major factors fueling the growth of this market in APAC. The aging population in China and Japan has resulted in rising labor costs, leading to the growing adoption of automation. The increasing population is also attracting companies to invest in APAC. The presence of some of the most prominent players in the industrial robotics market space, such as FANUC (Japan), Yaskawa (Japan), and Mitsubishi Electric (Japan), is another major factor driving the market in this region.

key players in the industrial robotics market include FANUC Corporation (FANUC (Japan)), ABB (Switzerland), Yaskawa Electric (Yaskawa (Japan)), KUKA (Germany), Mitsubishi Electric (Japan), Kawasaki Heavy Industries (Japan), DENSO (Japan), Nachi-Fujikoshi (Japan), Seiko Epson (Japan), and Dürr (Germany), among others.

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Aashish Mehra

Email: Send Email

Phone: 18886006441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL 60062

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/Industrial-Robotics-Market-643.html